Super User

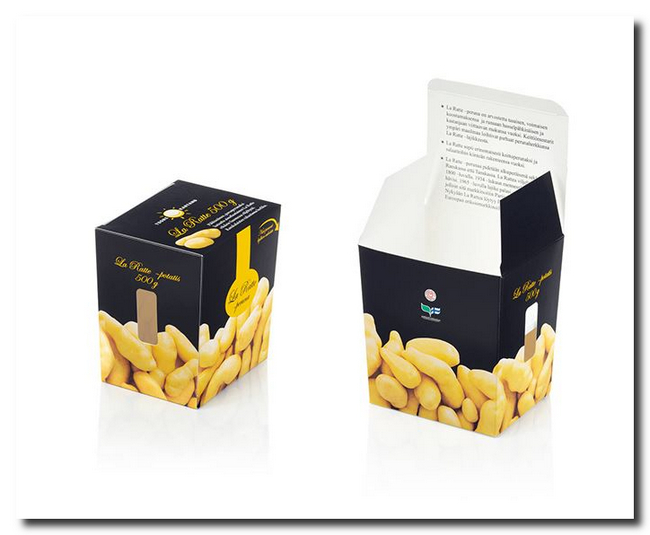

Luxury potatoes packaged responsibly

A plastic-reducing alternative to potato packaging has been introduced by Finnish Tuorekartano Oy when it recently launched its special potatoes in paperboard packaging. Tuorekartano Oy's premium quality La Ratte potatoes will now be packed in easily recyclable and biodegradable packaging made of a lightweight and durable paperboard produced by Metsä Board, part of Metsä Group. The paperboard is ideally suited to protect the potatoes from damage and sunlight. The small package size will also help to reduce food waste.

"Tuorekartano is a company committed to Agenda 2030 and Commitment 2050 and has set itself clear sustainability targets. Plastic-free packaging, such as La Ratte cartons, is part of these goals. We have already reduced the amount of plastic in our packaging materials by 25%," says Kari Kastari, CEO of Tuorekartano Oy.

The packaging is made of lightweight MetsäBoard Prime FBB EB paperboard, which is made from pure fresh fibres and is suitable for direct contact with food. The dispersion coating of the board improves the moisture and grease resistance of the board, and the packaging can be easily recycled and is also suitable for home composting.

"Environmental issues are important to us, which is why we are constantly improving our operations and production processes to make them more environmentally friendly. It is therefore important that the materials we use are recyclable and suitable for food contact. Metsä Board's paperboard meets our requirements both in terms of the environment and providing excellent printability," says Kalle Hurttila, Production Director at Hurtti-Paino Oy, the producer of the La Ratte packaging.

Metsä Board

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable resource, traceable to origin in sustainably managed northern forests. We are a forerunner in sustainability, and we aim for completely fossil free mills and raw materials by 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2020, our sales totalled EUR 1.9 billion, and we have about 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.

Stora Enso introduces portfolio for bio-based packaging foam

Stora Enso is extending its packaging offering with a new portfolio of bio-based foams from wood. The products are fully recyclable and can be used for protective and thermal packaging. Lightweight wood foams address the need for climate-friendly, renewable and circular cushioning materials in inner packaging.

Stora Enso’s offering consists of Fibrease™ by Stora Enso and Papira® by Stora Enso. Both foams come with versatile technical and sustainability properties, and customers can select a suitable foam based on their specific packaging requirements. The foams can be used for protecting fragile goods and are optimal for thermal packaging of temperature sensitive products. Fibrease is commercially available now, while the pilot plant for producing Papira has started operations at the Fors site in Sweden, following the investment announced in August 2020.

Fossil-based packaging is a major contributor to pollution, accounting for 40% of the world’s plastics. Today fossil-based materials, such as plastic wrap or polystyrene foams, are widely used as cushioning and insulating materials in packaging. With Fibrease and Papira, Stora Enso now introduces renewable and climate-friendly alternatives to fossil-based packaging protection. The bio-based foams come from certified wood and are recyclable in paper recycling streams.

“Consumers of today are pushing to minimise the use of plastic and maximise recyclability. At the same time, the need for packaging protection is increasing due to growing demands in e-commerce and cold-chain logistics. With our bio-based foams we help customers create eco-friendly and circular packaging solutions, while also meeting material performance needs to protect and insulate the goods,” says Markus Mannström, EVP Biomaterials at Stora Enso.

Stora Enso’s new pilot plant aims to evaluate and validate Papira as a packaging foam in customer tests. Stora Enso’s Fors site in Sweden, where the Papira pilot facility is located, produces lightweight paperboards for consumer packaging.

About Stora Enso’s wood foam products

Fibrease™ by Stora Enso is made with up to 98% renewable materials and designed to replace polyurethane (PU) foams and polystyrene (EPS) as well as formed in-place fossil-based solutions. Fibrease is a soft yet resilient material with a memory foam-like behaviour and can be fabricated by using different foam cutting techniques and thermoforming. It comes with a high insulating capacity and is suitable for thermal packaging, for example in online grocery sales and medicine shipments. The foam is recyclable in the paper and board stream and optimal for recycling in closed loops to new material and products.

Papira® by Stora Enso is a fully bio-based and biodegradable foam that is fully recyclable in any paper stream. It is a rigid yet flexible foam that provides high protection against shock and offers a plastic-free alternative to polymeric foams such polyethylene (PE), polystyrene (EPS) and polyurethane (PU). Papira is designed for optimal protection of fragile, sensitive and high-value consumer goods such as electronics as well as industrial appliances. It can be fabricated by using different foam cutting techniques and lamination.

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 23 000 employees, and its sales in 2020 were EUR 8.6 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). storaenso.com

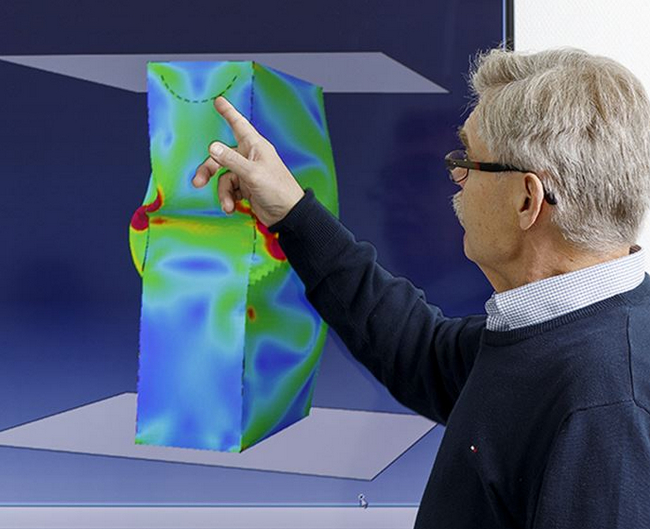

Metsä Board minimises environmental impact of packaging with Dassault Systèmes’ simulation platform

Metsä Board, the leading European producer of premium fresh fibre paperboards and part of Metsä Group, has successfully started to deploy Dassault Systèmes’ 3DEXPERIENCE platform in development and testing of packaging solutions at its Excellence Centre. With packaging simulation Metsä Board can notably speed up packaging development and reduce carbon footprint of packaging.

Simulation enables 85% faster development compared to the traditional way of making multiple tests with physical prototypes. Simulation technologies help manage the development of the entire product life cycle, from material selection to delivery. The new technology helps Metsä Board recommend optimal packaging materials as well as packaging structures to its customers.

“We wanted to accelerate our rate of innovation to help our customers – packaging manufacturers as well as brand owners – with optimal packaging solutions and reduce their carbon footprint. For example, box compression as well as drop tests can now be made in hours compared to several days or even weeks with traditional physical testing methods,” says Markku Leskelä, SVP Development, Metsä Board.

The state-of-the-art solution of Dassault Systèmes and their expertise from past engagements in the aerospace and automotive industry has helped deploy new technologies to the manufacturing of fibre-based packaging.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable resource, traceable to origin in sustainably managed northern forests. We are a forerunner in sustainability, and we aim for completely fossil free mills and raw materials by 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2020, our sales totalled EUR 1.9 billion, and we have about 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.

BillerudKorsnäs innovative solution on secondary packaging helps Oatly cut packaging carbon footprint by half

In partnership with BillerudKorsnäs, Oatly has implemented an innovative secondary packaging solution for products produced in Oatly’s Singapore Factory, enabling a reduction in secondary packaging material by up to 35% and an estimated reduction of CO2 emissions from secondary packaging by up to 50%*, compared to conventional packaging solutions.

BillerudKorsnäs, one of the leading global packaging companies, has partnered with Oatly, the world’s original and largest oat drink company, to develop innovative packaging solutions for Oatly’s Singapore produced products.

Oatly recently opened its first production facility in Asia to supply the nearby markets as part of the company’s global expansion. Products produced in the factory will be packed in boxes and transported on pallets during demanding climate conditions offering hot and humid weather which generates challenging logistics chains.

The conventional packaging solution to manage high humidity is adding additional material for sturdier packaging. But the team at BillerudKorsnäs BoxLab found a different solution to ensure enhanced sustainability performance while maintaining the high quality standards of Oatly’s secondary packaging. This innovative solution is based on the following principles:

- Minimizing damage and waste throughout the logistics chain

- Focus on resource efficiency – using as little material as possible and minimize water usage

- Use packaging material that is recyclable and comes from renewable sources

- Transparency throughout the value chain securing renewable energy sources

This solution is the result of the partnership between Oatly and BillerudKorsnäs and proves the potential of addressing packaging challenges differently to ensure the sustainability performance is a key priority.

“To challenge conventional packaging solutions for a sustainable future has long been the guiding star for BillerudKorsnäs. Oatly is a company that strives to produce sustainable and responsible products. We think alike in many ways,” says Henrik Ahlgren, Sales Director Asia & Pacific, BillerudKorsnäs.

Packaging material based on strong primary fibres can make a remarkable difference in demanding logistics chains. The reduction in secondary packaging material with up to 35% will generate substantial savings of packaging material per year.

The renewable paper material originates from responsibly managed forests.**

After use, the packaging can be recycled and used for less demanding packaging multiple times.***

“We always look to find solutions to make our production chain more sustainable, transparent and resource efficient. Therefore it’s great that we are able to work with BillerudKorsnäs to find this solution to lower the climate impact and optimize the design of our Asian packaging,” says Jenny Belsö Trojer, Global Cat Manager Packaging Material at Oatly.

For more information please visit BillerudKorsnäs´website: www.billerudkorsnas.com/insights/all/oatly-case

*Based on BillerudKorsnäs´ Environmental Assessment Tool comparing BillerudKorsnäs´ packaging solution with conventional packaging solutions.

**www.billerudkorsnas.com/sustainability/sustainability-foundation/sustainable-wood-supply

***Paper fibres can be recycled many times but as the fibre quality deteriorates during each recycling process a reasonable amount of recycling loops is around 4-6 times, depending on paper quality.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production units in Sweden, Finland and the UK and about 4500 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 24 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

MM Group has committed to net zero emissions until 2050

The Mayr-Melnhof Group (MM) has joined the global "Business Ambition for 1.5°C" initiative to contribute to limiting global warming to 1.5 degree through appropriate measures. As part of this initiative, launched by the UN Global Compact and Science Based Targets initiative (SBTi), among others, MM commits to setting science-based targets to seek for net-zero emissions in the whole value chain by 2050 at the latest. MM thus increases the pace of engagement on climate change at the time of major global milestones such as the UN Climate Change Conference COP26.

The Mayr-Melnhof Group (MM) has joined the global "Business Ambition for 1.5°C" initiative to contribute to limiting global warming to 1.5 degree through appropriate measures. As part of this initiative, launched by the UN Global Compact and Science Based Targets initiative (SBTi), among others, MM commits to setting science-based targets to seek for net-zero emissions in the whole value chain by 2050 at the latest. MM thus increases the pace of engagement on climate change at the time of major global milestones such as the UN Climate Change Conference COP26.

Peter Oswald, CEO of the MM Group: "MM is a Sustainability Company at the forefront of plastic waste prevention with innovative recyclable packaging made from renewable raw materials. In addition, the reduction of greenhouse gas emissions to mitigate climate change is an integrated and integral part of our corporate strategy. That’s why we set ourselves ambitious, science-based targets and take an active part in the Business Ambition for 1.5°C initiative to jointly drive a climatefriendly economy."

MM is Europe's leading producer of cartonboard and folding cartons with an attractive offer in Uncoated Fine Papers and Packaging Kraft Papers. The focus is on sustainable and innovative fiber-based packaging solutions. Including the latest acquisitions, MM generates sales of approximately EUR 3.2 billion and employs around 12,500 people.

Cybersecurity at the highest level

OPTIMA collaborates with LANCOM Systems to develop a novel VPN solution for machines

The Optima Group from Schwaebisch Hall, Germany, has joined forces with cybersecurity specialist LANCOM Systems to develop a new type of VPN solution for machines and systems. As a result, it is now possible to establish an even more secure connection with the systems installed at the customer's site and maintain them remotely. The solution, which is the only one of its kind on the market, allows for VPN connections monitoring, protects the machine network at the customer's site with a firewall and is particularly user-friendly.

Markus Irle, Vice President Firewall & Security at LANCOM Systems, and Dr. Eng. Benjamin Haefner, Group Leader Industrial IT at Optima, presenting the new VPN solution. (Source: Optima. All photos were taken in compliance with the strictest infection control measures.)

Markus Irle, Vice President Firewall & Security at LANCOM Systems, and Dr. Eng. Benjamin Haefner, Group Leader Industrial IT at Optima, presenting the new VPN solution. (Source: Optima. All photos were taken in compliance with the strictest infection control measures.)

"With LANCOM Systems, we have found the ideal partner to take our cybersecurity to the next level," says Dr. Eng. Benjamin Haefner, Group Leader Industrial IT at Optima. In the future, every machine built by the special-purpose machine manufacturer will be equipped with an edge firewall from LANCOM that has been specially developed for Optima. "In addition to the highest security VPN routing functionality, the edge firewall functions as a kind of central doorman in the machine. As a result, uncoordinated data flows with potential risks can be systematically reduced and controlled," explains Haefner.

Unparalleled functionalities for maximum security

In addition, the VPN connection between Optima and the machines at the customer's site can be permanently monitored with what is known as a central firewall. "These functionalities are one-of-a-kind on the market and ensure maximum IT security," says Haefner. The structure of the entire VPN solution is strictly aligned with standards relevant to cybersecurity, such as IEC 62443 or CPwE reference architecture.

With the new VPN connection and its special security features, Optima and LANCOM Systems offer Optima’s customers a particularly secure and user-friendly solution. In the future, every machine manufactured by this special-purpose machine builder will be equipped with it. (Source: Optima)

With the new VPN connection and its special security features, Optima and LANCOM Systems offer Optima’s customers a particularly secure and user-friendly solution. In the future, every machine manufactured by this special-purpose machine builder will be equipped with it. (Source: Optima)

User friendliness increases IT security

The LANCOM solution is also user-friendly and easy to operate. In addition, the automated solution can be configured for the customer's network faster than previous applications. There is plenty of freedom for making flexible adjustments to the customer's individual IT infrastructure, which facilitates harmonious integration. Retrofitting can be carried out on existing machines at any time. "Usability is a particularly important issue for us," adds Markus Irle, Vice President Firewall & Security at LANCOM Systems. "This is because a large proportion of cybersecurity incidents are due to errors in use, not the security technologies themselves." Such a challenge can be overcome by making the system less complex. The development partnership with LANCOM Systems is part of an extensive series of measures Optima has taken to further enhance cybersecurity.

Highly respected manufacturer of secure, reliable and future-proof network and security solutions

High-tech in action: An Optima employee checks the correct configuration of the VPN solution using a tablet. (Source: Optima) Based in Wuerselen, Germany, LANCOM Systems is a highly respected manufacturer of secure, reliable and future-proof network and security solutions (WAN, LAN, WLAN & firewalls) for business and government. For the fifth time in a row, the German network infrastructure provider has topped the Professional User Rating Security Solutions (PUR-S) user survey conducted by the analyst firm techconsult and boasts an excellent reputation among experts. LANCOM Systems is a wholly owned subsidiary of the Rohde & Schwarz technology group.

High-tech in action: An Optima employee checks the correct configuration of the VPN solution using a tablet. (Source: Optima) Based in Wuerselen, Germany, LANCOM Systems is a highly respected manufacturer of secure, reliable and future-proof network and security solutions (WAN, LAN, WLAN & firewalls) for business and government. For the fifth time in a row, the German network infrastructure provider has topped the Professional User Rating Security Solutions (PUR-S) user survey conducted by the analyst firm techconsult and boasts an excellent reputation among experts. LANCOM Systems is a wholly owned subsidiary of the Rohde & Schwarz technology group.

More information: www.optima-packaging.com/cybersecurity

About OPTIMA

Optima supports companies worldwide with flexible and customer-specific filling and packaging machines for pharmaceuticals, consumer goods, paper hygiene and medical devices markets. As a provider of solutions and systems, Optima accompanies these companies from the product idea through to successful production and throughout the entire machine life cycle. Over 2,650 experts around the globe contribute to Optima's success. 19 locations in Germany and abroad ensure the worldwide availability of services.

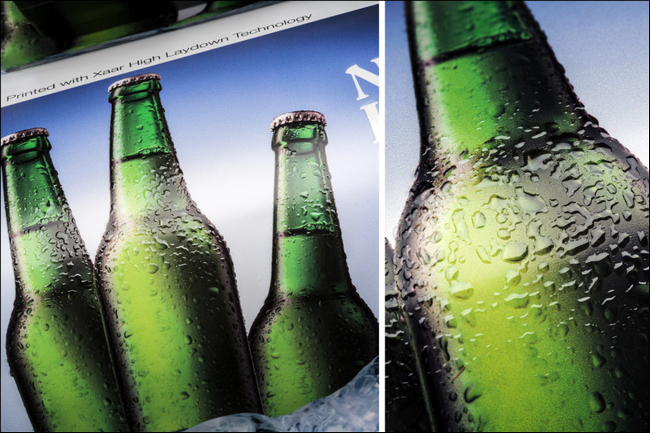

XAAR TO HIGHLIGHT INKJET’S GROWING SIGNIFICANCE FOR PACKAGING AT THE FUTUREPRINT & PACK SUMMIT

Xaar is presenting at this month’s FuturePrint & Pack Summit just how, within the world of packaging, inkjet is now truly coming of age.

The presentation, by Graham Tweedale, General Manager of Xaar’s Printhead Business Unit, will form part of this hybrid event, taking place live on 11th November in Cambridge, with digital content streamed globally on a weekly basis from November 18.

Titled, ‘Staying relevant for packaging in an ever-changing world’, Graham will show how recent innovations and Xaar’s ImagineX platform, are driving its importance as an effective, transformational technology for the printing of packaging.

Building on Xaar’s vision that strives to create “a world where you can print anything you can imagine”, Graham will set out an array of recent developments that will help put inkjet at the forefront of the packaging industry’s thinking.

From lightning print speeds of up to 48kHz at 100 metres per minute and the use of ink and fluid viscosities up to 100cP, to adding embellishments for the latest in personalisation and tactile, high-end packs, Xaar’s inkjet technologies are opening up a host of new opportunities for the packaging industry.

“Xaar’s ImagineX platform has been instrumental in the development of genuinely practical innovations that address and overcome some of the long-standing roadblocks in the application of inkjet in the packaging sector,” said Graham.

“It is clear that inkjet has much to offer in driving customer pack experience and now is the time for the sector to embrace this technology’s true potential. I very much look forward to sharing this insight at the FuturePrint & Pack Summit and be a part of what should be a fascinating event.”

About Xaar

Together with our partners and customers, Xaar has been transforming the world of inkjet technology for 30 years – and we’re just getting started.

With a new leadership team, new technology and new products, we have an exciting roadmap for the future – that will help our partners unleash the true power of inkjet printing and open up a world of opportunities for their business.

We believe true innovation comes from collaboration, which is why all our teams work together in Cambridgeshire where industrial inkjet was born.

Collaboration is at the core of our global partnerships too - whether we’re helping customers enhance their uptime or create production efficiencies from high-speed digitisation - we’re always innovating together.

We know that inkjet technology can not only maximise the efficiency of our partners’ businesses but help them evolve too. That’s why we go on a journey with our customers - offering expert insights and technical support every step of the way. Just like our printheads, Xaar’s partnerships are built to last.

Welcome to a whole new Xaar.

www.xaar.com

Hoogstraten’s recycled packaging ensures sustainable strawberry production

Hoogstraten is putting sustainability first by using recycled carton punnets for their premium strawberries, which are available all year round and supplied directly to the UK.

Coöperatie Hoogstraten has switched to carton punnets for their standard strawberry packaging, making a big step in reducing plastic waste, as the new carton punnet is made from more than 90% recycled carton, and is also recyclable.

The mission statement of Hoogstraten is "Together shaping a sustainable future in fresh fruit and vegetables through craftsmanship and high-quality services". They pride themselves on producing strawberries that are globally renowned for their flavour and quality. The cooperative is based near Antwerp. Throughout October and November, Belgium is the main source of strawberries in Europe.

Synnøve Johansson, Business Development Manager at Hoogstraten, says: “An additional benefit of the new carton punnet is the labour costs that are reduced for our growers. Our new machinery assembles each punnet and places them in a pre-assembled carton pallet, ready to be sent to the grower. This is a helpful tool that is now more useful than ever, as it simplifies the process and saves additional labour for when it comes to picking and packing the fruit.”

Packaging material remains one of the largest contributors to the cooperative’s CO2 footprint. Because of this, Hoogstraten are working with their carton punnet supplier to see how they can jointly further improve this impact in the future.

Johansson adds: “Due to their delicate nature, strawberries are unlikely to be sold loose, and so deciding on the most suitable and sustainable packaging is not always a simple choice. We have invested in an LCA tool to assist us in our evaluation of different packaging options, as it is about more than just reducing our environmental impact or using recycled plastic.

“Other practical factors also need to be considered when it comes to packaging, such as the raw material used, food safety concerns and the shelf life of the product.

- The UK promotional campaign is run by Coöperatie Hoogstraten.

- Hoogstraten is the cooperative specialising in fruits, with a passion for quality.

- The main strawberry varieties grown by Hoogstraten are:

- Elsanta: Red and tasty, accounts for most of the strawberries marketed by Hoogstraten

- Sonata: Fresh red, round and sweet. Perfect for enlightened crop in winter and very successful in spring.

- Sonsation: Sweet with an intensive gloss. Looks like Sonata, but the red colour appears to be more intense.

- Limalexia: Fruits with a pleasant texture and excellent taste. Looks like Elsanta, but the fruit size throughout the growing season is better maintained.

- Murano: Everbearer with appearance of a June bearer.

- All strawberries sold at Hoogstraten are grown locally in Belgium, or just across the border in the south Netherlands.

- Strawberries account for approximately 50% of Hoogstraten’s turnover.

- Every year approximately one third of the strawberry volumes are sold domestically, while two thirds are exported, to the UK and other markets. From September through to mid-December around 80% of Hoogstraten’s volumes are exported.

- The UK marketing campaign for Hoogstraten strawberries began in September this year.

- Scandinavia, UK and France are the largest export market for Belgian strawberries, due to the market favouring fresh products.

WestRock Again Honored for Innovative Design Excellence by Paperboard Packaging Council

Company Receives 14 Awards at Annual Paperboard Packaging Competition, Including Sustainability Award of the Year

WestRock Company (NYSE: WRK), a leading provider of differentiated paper and packaging solutions, was recognized for packaging design excellence at the 78th Annual North American Paperboard Packaging Competition. The company won a total of 14 awards, including Sustainability Award of the Year, reinforcing its commitment to imagining and delivering on the promise of a more sustainable future.

Sponsored by the Paperboard Packaging Council (PPC) and judged by packaging experts, the awards recognize best-in-class innovative and sustainable packaging designs in the North American folding carton industry.

WestRock CanCollar®, with Coca-Cola Europacific Partners and LERVIG Brewing, received the Sustainability Award of the Year. CanCollar is an innovative family of fiber-based multipack solutions for canned beverages that enables brands to transition from single-use plastic rings and shrink film into recyclable paperboard solutions. Whether they require minimal material usage, lid coverage for hygiene, or bar-code masking and billboard space for brand messages, the CanCollar family of designs and the CanCollar Fortuna® packaging machinery platform offer brands an array of sustainable packaging options.

WestRock was recognized with 14 awards for packaging design excellence at the 78th Annual North American Paperboard Packaging Competition. Pictured: WestRock CanCollar®, with Coca-Cola Europacific Partners and LERVIG Brewing, received the Sustainability Award of the Year. (Photo: Business Wire)

WestRock was recognized with 14 awards for packaging design excellence at the 78th Annual North American Paperboard Packaging Competition. Pictured: WestRock CanCollar®, with Coca-Cola Europacific Partners and LERVIG Brewing, received the Sustainability Award of the Year. (Photo: Business Wire)

“We’re honored to be recognized by the Paperboard Packaging Council for our innovativepackaging designs,” said Patrick Kivits, president of Consumer Packaging at WestRock. “We celebrate this achievement alongside our customers, who were instrumental in bringing our winning solutions to markets. Working together, we are delivering on our promise of a more sustainable future.”

In addition to the Sustainability Award of the Year, WestRock received seven Gold awards and six Excellence awards for a variety of packaging solutions. For more information, including photos of the winning packaging innovation, visit https://www.westrock.com/ppcawards2021.

A full list of the winners is included below:

- WestRock CanCollar® with Coca-Cola Europacific Partners, LERVIG Brewing, Sustainability Award of the Year

- WestRock Cluster-Wing™ with Kraft Heinz, Gold Award, Outstanding Achievement in Sustainability and Innovation

- TAO Sushi Carton, Gold Award, Outstanding Achievement in Sustainability and Innovation

- Columbia Classics Collection, Gold Award, Outstanding Achievement in Innovation

- Sally Hansen Mentos Gift Pack, Gold Award

- Raasay Single Malt Whisky, Gold Award

- Nestlé Smarties Hexatube, Gold Award

- WestRock EcoPush™ with Chagrin Valley, Gold Award

- Colgate Optic White, Excellence Award, Achievement in Sustainability

- Stella Artois Midnight Lager, Excellence Award

- Oozlefinch/Hop Culture FML Fest Shipper & Photo Box Set, Excellence Award, Achievement in Innovation

- Sleeman Bag Toss Hack Pack, Excellence Award

- Die Besten von Ferrero Adventskalender, Excellence Award

- The Hershey Company Reese's Holiday Miniatures, Excellence Award

About WestRock

WestRock (NYSE: WRK) partners with our customers to provide differentiated, sustainable paper and packaging solutions that help them win in the marketplace. WestRock’s team members support customers around the world from locations spanning North America, South America, Europe, Asia and Australia. Learn more at www.westrock.com.

Source: WestRock Company

PulPac continues to accelerate commercialization of Dry Molded Fiber - Appoints Conny Högström as Tech Center Manager

PulPac takes another important step in the global commercialization of its innovative manufacturing technology for fiber-based packaging and appoints Conny Högström as Manager for the company's Tech Center.

Conny Högström joins the expanding team of skilled professionals as Tech Center Manager, a new position, to support the continued commercialization of Dry Molded Fiber. Conny most recently comes from a position as Operations Manager at Seldén Mast AB, the world’s biggest manufacturer of standardized and customized yacht rigs. Conny brings a profound experience as a leader, having been responsible of development of teams, operations, facilities, special projects, strategic and daily production coordination, including organizing, planning, and running production activities and improving processes and routines.

“I am very happy to be part of the fantastic journey that the PulPac team have set out on. I am passionate about getting staff and projects to go hand in hand, while achieving great results. That is how I believe I can contribute to the accelerated development of the Tech Center and the amazing Tech Center team. I am humbled by all the collective knowledge and know-how found in this competent team and look forward to strengthening and streamlining our support to the organization and the Dry Molded Fiber community, all with the clear focus to replace single-use plastics, which feels very rewarding” says Conny Högström, new Tech Center Manager at PulPac.

The PulPac Tech Center holds world-leading know-how within Dry Molded Fiber. The dedicated Tech Center team has unique expertise within tooling, application and material development, industrialization and production adaptation and supports clients and partners in the Dry Molded Fiber community.

“Now was the time to broaden our team and Conny, with his solid technical background combined with experience from a leading position in production and operations management, will allow us to further capitalize on the strength of Dry Molded Fiber as we continue to innovate, commercialize and grow - I’m very excited that Conny is joining the team” says Sebastian Roos, Chief Technology Officer at PulPac.

Conny took office on October 18.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally. www.pulpac.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy – using renewable pulp and cellulose resources to produce low cost, high performance, fiber-based packaging, and single-use products. Dry Molded Fiber gives up to 80-90% lower CO2 footprint at similar cost as plastic. It is up to ten times as efficient as conventional fiber molding invented over 100 years ago. The dry process also saves massive amounts of valuable water resources. In addition, energy savings are significant - as the molded products need no drying.