Displaying items by tag: PulPac

PulPac, Nordic barrier coating and OrganoClick have been granted funding from BioInnovation for developing PFAS- and plastic-free barriers for food packages

The consortium of PulPac, Nordic Barrier Coating and OrganoClick has been granted financial support for continued development of 100% biobased, plastic- and PFAS-free barriers and materials for demanding food packaging applications. The development project is funded from the Swedish strategic innovation program BioInnovation financed by the Swedish innovation agency Vinnova.

Following breakthroughs made last 2021, the consortium will continue the project that focuses on integration of commercially scalable environmentally friendly water and/or grease resistant barriers specialized in Dry Molded Fiber.

Viktor Börjesson, Chief Partnership Officer at PulPac comments, “We are very proud about the breakthroughs achieved within BioInnovation with our partners. The combined performance in OrganoClick’s chemistry and scalability coupled with NBC’s dynamic ability to form specialized materials makes this a very important project. Dry Molded Fiber is disrupting fiber forming, making it possible to manufacture paper packaging without wasting valuable water resources or energy and significantly reducing CO2, at unit economics that are very competitive. These solutions are plastic-free, biodegradable and recyclable – very important qualities to our customers.”

Challenging packaging applications for Dry Molded Fiber is the target of the R&D consortium

Challenging packaging applications for Dry Molded Fiber is the target of the R&D consortium

Dan Blomstrand, VP Biocomposites at OrganoClick AB, comments “We are very eager to continue building on the breakthroughs reached in step one of this BioInnovation program. The potential markets being enabled in packaging and single-use products with our 100% biobased and home compostable coating and binder products for Dry Molded Fiber by PulPac are enormous.”

Urban Winberg, CEO at Nordic Barrier Coating AB, comments “The delicate art of designing materials and combining functions from OrganoClick’s chemistry adapted for Dry Molded Fiber has yielded very exciting opportunities as shown in last year’s breakthroughs. We can now invest in infrastructure and industrial capacity to commercially pilot the solutions discovered, and to cater to Dry Molded Fiber's global uptake.”

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

About Nordic Barrier Coating

Nordic Barrier Coating AB manufactures and offers innovative barrier and packaging solutions for maximum functionality. Specialised on extrusion on paper, plastic and non-woven. With many years of experience from the paper, extrusion and conversion industries, we possess cutting-edge expertise in the field. www.nbcab.se

About OrganoClick

OrganoClick AB (publ) is a public Swedish cleantech company listed on Nasdaq First North Growth Market. The company develops, produces and markets functional materials based on environmentally friendly fiber chemistry. Examples of products that are marketed by OrganoClick are the durable water repellent technology for textiles OrganoTex®, the biocomposite material OrganoComp®, surface treatment and maintenance products for villa and property owners under the brand BIOkleen®, biobased binder under the trade name OC-BioBinder™ and the flame and rotresistant timber OrganoWood® (through the joint-venture OrganoWood AB). OrganoClick was founded in 2006 as a commercial spin-off company based on research performed at Stockholm University and the Swedish University of Agricultural Sciences within environmentally friendly fiber chemistry. www.organoclick.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy. It leverages globally available, affordable, and renewable cellulose fibers to produce high performance fiber-based packaging and single-use products with highly competitive unit economics. Dry Molded Fiber also saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is up to ten times as efficient as conventional fiber molding invented over 100 years ago.

Global mould specialist dexter MT new partner in PulPac’s expanding Dry Molded Fiber network

In a world searching for alternatives to plastics, the market pull for Dry Molded Fiber is enormous. To effectively scale and support converters in the transition to the new technology, PulPac continuously expands the network of preferred partners and suppliers. dexter Mould Technology, specialist in designing, developing, and building high quality moulds for the thermoforming process, now becomes part of this global network of leaders supporting the Dry Molded Fiber community.

“We are excited to join this network of innovative and proficient leaders. Innovation is part of our daily work and doing business sustainably is a given. By working closely and in long-term partnerships with our customers, we know what the market needs. The packaging industry is transforming, and we strongly believe in Dry Molded Fiber as a new standard for sustainable packaging. By applying our expertise and craftmanship in mould making to this pioneering technology we can support existing and new customers in their transition to fiber-based alternatives”, says Jeroen Berns, Sales Manager at dexter Mould Technology.

Dry Molded Fiber, invented and patented by PulPac, is available to converters, brands and partners that seek to be part of the transition towards truly sustainable fiber-based packaging. Besides unmatched sustainability features the unique fiber forming technology offers unit economics competitive enough to make a viable shift from single-use plastics to fiber-based alternatives.

dexter Mould Technology, specialist in designing, developing, and building high quality moulds for the thermoforming process, has joined PulPac’s worldwide network supporting the dry molded fiber community.

dexter Mould Technology, specialist in designing, developing, and building high quality moulds for the thermoforming process, has joined PulPac’s worldwide network supporting the dry molded fiber community.

“Converters all over the world are ready and eager to develop their business with fiber-based alternatives. dexter MT is a recognized and established toolmaker that brings world-leading knowledge, experience of high-quality mould-making and capacity to the Dry Molded Fiber network. By working together, we can scale quickly and give converters access to quality-assured production tools”, says Sanna Fager, Chief Commercial Officer at PulPac.

About dexter Mould Technology

dexter Mould Technology has been building moulds for the thermoforming industry since 1964. The word ‘dexter’ in Latin means ‘skilful’. And ever since we started working in this specialised field, craftsmanship has been the mainstay of the dexter Group. We never stop innovating, and because we work closely with the top suppliers of thermoformers, we know exactly what the market needs.

For additional information about dexter Mould Technology, please visit https://dextermt.nl or follow us on social media.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy. It leverages globally available, affordable, and renewable cellulose fibers to produce high performance fiber-based packaging and single-use products with highly competitive unit economics. Dry Molded Fiber also saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is up to ten times as efficient as conventional fiber molding invented over 100 years ago, and the process has typical outputs that are comparable to those of the thermoforming process.

Solenis Joins as New Partner in PulPac’s Expanding Dry Molded Fiber Network

Global leader in specialty chemicals for paper packaging to provide sustainable barrier coating solutions

In a world desperate for alternatives to plastics, the market-pull for dry molded fiber is enormous. To support converters in the transition to the new technology, PulPac continuously expands its network of preferred partners and suppliers. Solenis, a leading global producer of specialty chemicals focused on delivering sustainable solutions, has joined this global network of leaders supporting the dry molded fiber community.

“We are excited to be a force for sustainable change in the packaging industry by contributing to this groundbreaking technology. Solenis has a prominent culture of innovation, consistently delivering new-to-the-world products and next-generation technologies to meet the ever-changing market needs and challenges our industrial customers face. I believe we are uniquely positioned to provide safe and sustainable barrier solutions designed for circularity to the dry molded fiber converters that lead the way and set new standards for fiber-based packaging,” says Daniel Palrén, Business Development Manager at Solenis. “Fiber-based products coated with these barrier coatings typically are repulpable, recyclable, compostable and biodegradable, thereby offering packaging producers a way to improve their sustainability credentials with brand owners, retailers and consumers.”

Solenis, a leading global producer of specialty chemicals, has joined PulPac’s worldwide network supporting the dry molded fiber community

Solenis, a leading global producer of specialty chemicals, has joined PulPac’s worldwide network supporting the dry molded fiber community

Dry Molded Fiber, invented and patented by PulPac, is a fiber-forming technology available to converters, brand owners and partners to help create a new and competitive standard in sustainable packaging. The pioneering technology is designed for the circular economy and uses affordable, globally available, renewable cellulose fibers to produce high-performance, fiber-based packaging and single-use products with highly competitive unit economics. Saving significant amounts of valuable water resources and energy, a dry molded fiber product can have up to 80% lower CO2 footprint compared to alternatives.

“Collaboration is key to putting an end to plastic pollution. By working together with leaders such as Solenis, we expand capabilities, expertise and capacity and speed up the on-going global transition to fiber, away from single-use plastics. The collaboration already shows very good results and together with Solenis’ reach, know-how and platform as a leading global chemistry supplier in fiber, we can work wonders on barrier technology,” says Linus Larsson, Chief Executive Officer at PulPac.

About Solenis

Solenis is a leading global producer of specialty chemicals, focused on delivering sustainable solutions for water-intensive industries, including the pulp, packaging paper and board, tissue and towel, oil and gas, petroleum refining, chemical processing, mining, biorefining, power, municipal, and pool and spa markets. The company’s product portfolio includes a broad array of water treatment chemistries, process aids and functional additives, as well as state-of-the-art monitoring and control systems. These technologies are used by customers to improve operational efficiencies, enhance product quality, protect plant assets, minimize environmental impact and maintain healthy water. Headquartered in Wilmington, Delaware, the company has 47 manufacturing facilities strategically located around the globe and employs a team of over 6,000 professionals in 120 countries across five continents. Solenis is a 2021 US Best Managed Company.

For additional information about Solenis, please visit www.solenis.com

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com

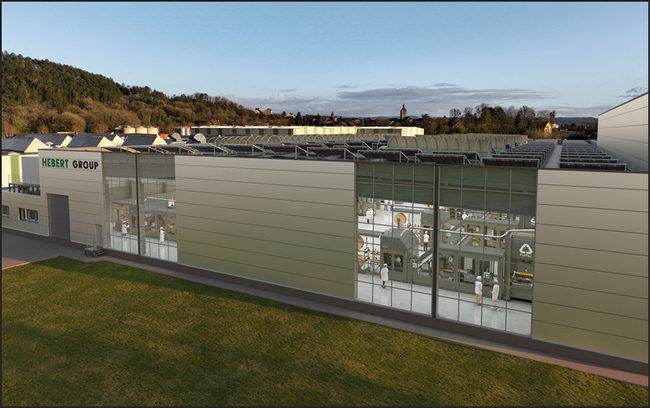

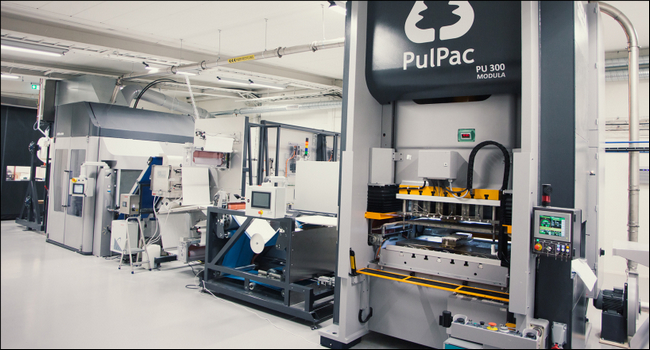

Hébert Group joins forces with PulPac and sets up Dry Molded Fiber production

Hébert Group becomes a licensee and sets up production with PulPac’s pioneering Dry Molded Fiber technology. The production platform “PulPac Modula”, developed by PulPac and its partners, will be installed this summer in their facilities located in Orgelet, in the East of France.

Hébert Group has a history of constant focus on innovation and looking to the future, with sustainability as a key driver. With an expertise in thin wall packaging and in-mould labelling, the company supports some of the biggest brands in the global food industry.

Julien Hébert, Technical & Sales Director, Hébert Group said “We believe that the packaging industry is entering a new era driven by fast-evolving regulatory systems and customer expectations. At Hebert Group, we take pride in being in the forefront of that market shift and our collaboration with PulPac will allow us to develop and manufacture truly competitive fiber-based solutions. PulPac’s pioneering technology is not only about strengthening our offering and our customers’ brands, but also about leading the way in our industry.”

Dry Molded Fiber, invented and owned by PulPac, is a fiber forming technology that can replace single-use plastic with sustainable fiber-based alternatives at low cost. To accelerate the shift, PulPac has together with partners developed the PulPac Modula standardized machine platform. The company is on a mission to replace single-use plastics at scale, and this is a first in a stream of Dry Molded Fiber machinery rolling out to licensees, setting a new standard for sustainable fiber-based packaging.

Sanna Fager, Chief Commercial Officer, PulPac said “We are truly impressed by Hébert Group’s innovative mindset and ability to adapt to new technology, which has created very solid partnerships with some of the biggest names in the global food industry. We look forward to a long-term partnership where we can share know-how and expertise to leverage the full potential of dry molding within Hébert Group’s operations and customer network.”

About Hébert Group

Hébert Group is a family-owned company with an expertise in the development and the manufacturing of packaging solutions for the food and cosmetic markets. They have been supporting key FMCG companies in the large-scale industrialization of some of the most iconic designs in the packaging industry. www.hebert-group.com

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally. www.pulpac.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy. It leverages globally available, affordable, and renewable cellulose fibers to produce high performance fiber-based packaging and single-use products with highly competitive unit economics. Dry Molded Fiber also saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is up to ten times as efficient as conventional fiber molding invented over 100 years ago.

Scandicore joins forces with PulPac and launches world’s first paper tube lids

Scandicore launches world’s first paper tube lids made with PulPac’s revolutionary Dry Molded Fiber technology. Bridge volumes will be manufactured by PulPac and first art print deliveries with the new lid are estimated to reach consumers this spring.

Scandicore, one of the Nordic region’s leading manufacturers of sustainable cores and tubes for the manufacturing industry, have together with PulPac, world leader and owner of Dry Molded Fiber, developed a paper lid to perfect the company’s paper tubes. One of Europe’s leading online stores for art prints will be first in line to offer their products in completely plastic free and fiber-based packaging from Scandicore.

“Safeguarding the environment and the quality of our products, are our primary competitive advantages. The physical strength of the Dry Molded Fiber products, in combination with resource efficiency, where valuable water resources and energy are saved, in addition to significant reductions of CO2, makes this a strategic investment for Scandicore. We have been listening to the market. This solution is heavily asked for by our customer and we are proud to start the journey to support the green and sustainable choice of our customer” says Eva Engström, CEO at Scandicore.

Dry Molded Fiber, invented and owned by PulPac, is a fiber forming technology that can replace single-use plastic with sustainable fiber-based alternatives at low cost. The patented technology is available to converters that set up their own production. To accelerate the shift, PulPac has together with partners developed the PulPac Modula standardized machine platform, now starting to roll out to licensees and available at the PulPac Tech Center for sample and bridge volume production.

“We offer a ‘wheat to bread’ setup, delivering application development, tool making, and sample production to ease the transition to Dry Molded Fiber. In close collaboration with our clients, we develop competitive, and sustainable market ready applications. The paper tube lid is a perfect fit for our technology, and we are happy to partner with Scandicore to bring this unique solution to the market”, comments Sanna Fager, Chief Commercial Officer at PulPac.

About Scandicore

Scandicore is one of the Nordic region’s leading manufacturers of paper cores for the manufacturing industry as well as a supplier of tubes for consumer market. Contribution of sustainable products with limited CO2 footprint is on the daily agenda of Scandicore as well as a long-term commitment. Scandicore AB is part of the family-owned industrial group, the Mustad United Group. www.scandicore.com

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally. www.pulpac.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy. It leverages globally available, affordable, and renewable cellulose fibers to produce high performance fiber-based packaging and single-use products with highly competitive unit economics. Dry Molded Fiber also saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is up to ten times as efficient as conventional fiber molding invented over 100 years ago.

PulPac files patent for tool that further improves functionality and efficiency for Dry Molded Fiber

PulPac has just announced the filing of an additional patent application, further refining its pioneering cellulose forming technology for competitive fiber-based packaging and single-use products.

The new patent application comprises a hybrid tool that uses the pressing force to work in mould parts both in a pressing direction and in a lateral direction. The hybrid tool efficiently uses one pressing stroke for manufacturing a product having a general form in the pressing direction and a special feature such as for example undercut in the lateral direction. This is especially advantageous when manufacturing products like lids and other applications where e.g. stacking and denesting features are important. The hybrid tool also brings possibility of enhanced surface quality and improved tool life.

“Innovation is a core function at PulPac. It is at our heart and how we drive change for a sustainable future together with our clients. This patent application is a good example on how we continuously can refine and make Dry Molded Fiber even more effective or adapt it to specific demands or product applications” says Peter Ekwall, IP Manager at PulPac

Dry Molded Fiber is a fiber forming technology that can replace single-use plastic with sustainable fiber-based alternatives at low cost.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally. www.pulpac.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy – using renewable pulp and cellulose resources to produce low cost, high performance, fiber-based packaging, and single-use products. Dry Molded Fiber gives up to 80-90% lower CO2 footprint at similar cost as plastic. It is up to ten times as efficient as conventional fiber molding invented over 100 years ago. The dry process also saves massive amounts of valuable water resources. In addition, energy savings are significant - as the molded products need no drying.

PulPac continues to accelerate commercialization of Dry Molded Fiber - Appoints Conny Högström as Tech Center Manager

PulPac takes another important step in the global commercialization of its innovative manufacturing technology for fiber-based packaging and appoints Conny Högström as Manager for the company's Tech Center.

Conny Högström joins the expanding team of skilled professionals as Tech Center Manager, a new position, to support the continued commercialization of Dry Molded Fiber. Conny most recently comes from a position as Operations Manager at Seldén Mast AB, the world’s biggest manufacturer of standardized and customized yacht rigs. Conny brings a profound experience as a leader, having been responsible of development of teams, operations, facilities, special projects, strategic and daily production coordination, including organizing, planning, and running production activities and improving processes and routines.

“I am very happy to be part of the fantastic journey that the PulPac team have set out on. I am passionate about getting staff and projects to go hand in hand, while achieving great results. That is how I believe I can contribute to the accelerated development of the Tech Center and the amazing Tech Center team. I am humbled by all the collective knowledge and know-how found in this competent team and look forward to strengthening and streamlining our support to the organization and the Dry Molded Fiber community, all with the clear focus to replace single-use plastics, which feels very rewarding” says Conny Högström, new Tech Center Manager at PulPac.

The PulPac Tech Center holds world-leading know-how within Dry Molded Fiber. The dedicated Tech Center team has unique expertise within tooling, application and material development, industrialization and production adaptation and supports clients and partners in the Dry Molded Fiber community.

“Now was the time to broaden our team and Conny, with his solid technical background combined with experience from a leading position in production and operations management, will allow us to further capitalize on the strength of Dry Molded Fiber as we continue to innovate, commercialize and grow - I’m very excited that Conny is joining the team” says Sebastian Roos, Chief Technology Officer at PulPac.

Conny took office on October 18.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally. www.pulpac.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy – using renewable pulp and cellulose resources to produce low cost, high performance, fiber-based packaging, and single-use products. Dry Molded Fiber gives up to 80-90% lower CO2 footprint at similar cost as plastic. It is up to ten times as efficient as conventional fiber molding invented over 100 years ago. The dry process also saves massive amounts of valuable water resources. In addition, energy savings are significant - as the molded products need no drying.