Super User

Nordic Paper explores further improved barriers for packaging

Nordic Paper is world leading within natural greaseproof papers used in different food applications, for example as baking papers, for baking cups or for food containers. The paper has natural barrier properties achieved without the addition of fluorochemicals, so called PFAS. To further develop these natural barriers and to expand the markets for natural greaseproof papers, Nordic Paper has entered into a two-year cooperation with Centre Technique du Papier, CTP, in France.

Nordic Paper produces and develops natural greaseproof papers for the food industry without addition of fluorochemicals. Barrier properties are important characteristics for these paper grades in order that the grease of the packaged foodstuff does not go through the paper. The initiated cooperation project with CTP focuses on exploring and developing further improved natural grease barriers without addition of fluorochemicals.

Nordic Paper produces and develops natural greaseproof papers for the food industry without addition of fluorochemicals. Barrier properties are important characteristics for these paper grades in order that the grease of the packaged foodstuff does not go through the paper. The initiated cooperation project with CTP focuses on exploring and developing further improved natural grease barriers without addition of fluorochemicals.

- Our papers are equipped with good and natural barriers for many application areas, but we are eager to push the limits and to increase the grease resistance even further of our products, says Henrik Kjellgren, product manager Natural Greaseproof.

CTP is a leading research institute for the paper industry with a specific competence in treatment of fiber surfaces and in barrier properties. Several laboratory tests will be conducted in the project which is expected to result in valuable information for the continued development work of Nordic Paper regarding further improved barriers. The ambition is to expand the market for greaseproof papers so that the customers of Nordic Paper would be able to produce packaging solutions for food that is currently packaged in plastic or aluminum-based solutions.

- One example of an application we are looking into is food trays for frozen lasagna where the packaging requires very good barrier properties as the food and its packaging undergoes heating, explains Henrik Kjellgren.

Nordic Paper is already today, with its greaseproof papers, able to offer more sustainable alternatives to packaging manufacturers currently using packaging solutions based on plastics or on materials with added fluorochemicals.

- We can contribute to the ongoing phasing out of the use of PFAS and to reduce plastics consumption in society. It is important that we take further steps to develop us into neighboring application areas where our papers are currently not present to increase our contribution to a sustainable society, concludes Henrik Kjellgren.

Nordic Paper is a leading specialty paper producer with its base in Scandinavia. We have been manufacturing top-quality kraft papers and natural greaseproof papers since the 19th century. Our products are based on renewable raw material from local forests. From our five paper mills, four in Scandinavia and one in Canada, we supply customers in about 80 countries. Nordic Paper had in 2021 net sales of approximately SEK 3,100m, about 690 employees and is listed on Nasdaq Stockholm. www.nordic-paper.com

Recyclable Grease-Resistant VCI Paper: Choose the VpCI®-148 Advantage!

What happens when a manufacturer needs to ship a metal part and protect it from corrosion, but the shipping process does not allow removal of process oil? Surprisingly, the answer is not to automatically use VCI plastic but to consider a product like VpCI®-148 Paper—a recyclable, grease-resistant, corrosion inhibiting packaging material produced by Cortec® Corporation and available for distribution worldwide.

Protect Metals from Corrosion

The main benefit of VpCI®-148 Paper is the same as all VCI papers: corrosion protection or rust prevention on the metals packaged within. Like Cortec’s other VpCI® Papers, VpCI®-148 Paper is coated with Vapor phase Corrosion Inhibitors. These protect not only the metal surfaces in direct contact with the paper but also those that are enclosed inside, but not directly touching, the paper. Vapors from the VpCI® coating diffuse throughout the interior of the package, forming an invisible protective molecular layer on the surfaces of the metal. When the metal component is removed from the packaging, the protective layer evaporates on its own—no manual removal needed.

The main benefit of VpCI®-148 Paper is the same as all VCI papers: corrosion protection or rust prevention on the metals packaged within. Like Cortec’s other VpCI® Papers, VpCI®-148 Paper is coated with Vapor phase Corrosion Inhibitors. These protect not only the metal surfaces in direct contact with the paper but also those that are enclosed inside, but not directly touching, the paper. Vapors from the VpCI® coating diffuse throughout the interior of the package, forming an invisible protective molecular layer on the surfaces of the metal. When the metal component is removed from the packaging, the protective layer evaporates on its own—no manual removal needed.

Eliminate Plastic Packaging

VpCI®-148 Paper can effectively replace the use of plastic VCI film or even plastic-coated papers. This is important in a day and age when industries are looking for more renewable resource alternatives to products made from fossil fuels. In addition to the base substrate of VpCI®-148 Paper being made with paper sourced from sustainable forestry, the barrier coating is fully recyclable/repulpable, unlike traditional PE- (polyethylene) or wax-coated papers that cannot be recycled through normal channels.

Resist Grease in Wider Applications

VpCI®-148 Paper holds up better than standard VCI paper in the presence of grease and process oils, allowing it to be used for rust preventative packaging of both dry and oiled metals during storage, transit, and overseas shipment. This is an important solution when protecting metal parts such as bearings that require lubrication, or those where the manufacturing or shipping process do not permit the removal of process oils. Such was the case for a manufacturer of SUV frames being shipped overseas to Germany. The previously used plastic VCI film (non-Cortec®) was breaking down due to aggressive process oils remaining on the frame, resulting in tarnish and corrosion that caused the frames to be rejected. Interestingly, VpCI®-148 Paper solved the unusual problem because it provided corrosion protection and sufficient barrier protection to keep the packaging from breaking down in the presence of process oil. Also, Cortec’s capability of making rolls almost 2.5 meters wide, larger than typical VCI paper, was well suited to wrapping and protecting the wide vehicle frames.

How and Where to Use Grease-Resistant VCI Paper

Thanks to the multiple features mentioned above, there are many potential applications for VpCI®-148. VpCI®-148 Paper protects both ferrous and non-ferrous metals and therefore can be used to protect a wide range of metal parts:

- Carbon Steel

- Stainless Steel

- Galvanized Steel

- Cast Iron

- Aluminum Alloys

- Copper

- Brass (≤30% Zn)

- Solder

VpCI®-148 should be applied by wrapping parts with the printed grease-resistant side facing out and the plain corrosion inhibiting side facing in as close to the metal surface as possible, folding the ends together and taping as necessary to create a closed environment inside the paper. VpCI®-148 Paper can also be used to wrap individual components in combination with a larger integrated packaging solution. It is great for interleaving between trays of parts coated with oil, grease, or process fluids, as well. The next time you have a packaging application that calls for corrosion protection in the presence of greasy or oily parts, consider whether VpCI®-148 Paper may be a sufficient—or even better—alternative to plastic in terms of performance and sustainability. Contact Cortec® to learn more about VpCI®-148 Paper today: https://www.cortecpackaging.com/contact-us/

PulPac continues to expand the Dry Molded Fiber patent portfolio

With two new patent applications filed last week, PulPac continues to expand the Dry Molded Fiber patent portfolio. The new patent applications are directed to ejection elements in connection to the forming mold. The main purpose of the ejection elements is to release the product from mold parts for an easy removal of the products. The ejection elements can also be used for imprinting a pattern in the product, to be read or scanned for information purposes.

Dry Molded Fiber is invented, patented and licensed to packaging manufacturers by PulPac. The game-changing technology is up to ten times faster than traditional fiber forming methods and offers highly competitive unit economics. In addition, being a dry process, it saves significant amounts of valuable water and energy, resulting in up to 80% lower CO2 emissions compared to alternatives.

Dry Molded Fiber - the fiber forming technology that can transform the industry and establish a new global standard for sustainable fiber-based packaging and single-use items.

Dry Molded Fiber - the fiber forming technology that can transform the industry and establish a new global standard for sustainable fiber-based packaging and single-use items.

To date, PulPac holds 28 patent families with 85 granted national patents and plus 50 pending patent applications. New patent applications are filed continuously. In addition, PulPac has a substantive body of know-how and trade secrets that are shared only within the Dry Molded Fiber network. Based on the core IP, PulPac has developed a complete technology platform covering multiple areas of fiber application manufacturing. All driven by the need of disruptive technical solutions that enable a sustainable packaging industry.

Peter Ekwall, CIPO, comments, “Innovations are detected and harvested every week, which gives us the possibility to rapidly expand our patent portfolio with good quality. We also see an increased interest from our partners to contribute to the patent and technology pool. All things considered; this is beneficial for everyone that wants to join us in our mission to replace single-use plastic as soon as possible.”

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com

Metsä Group’s 3D fibre product Muoto® is a significant new initiative in the packaging market

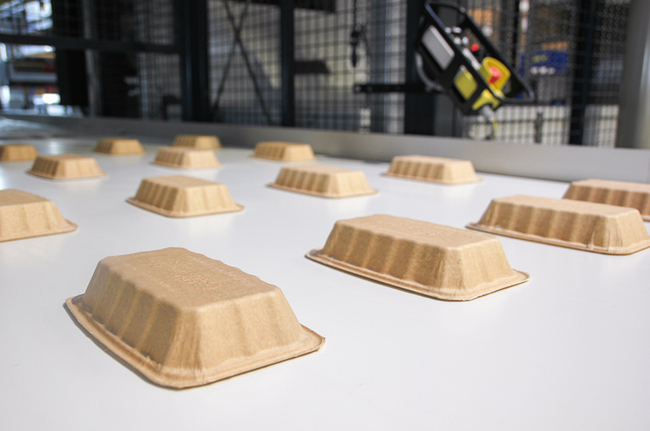

Metsä Spring, Metsä Group’s innovation company, has launched a new 3D fibre product called Muoto®. Muoto has been produced at Metsä Group’s and Valmet’s demo plant in Äänekoski since May 2022, and is made of Metsä Group’s wood fibres.

Muoto is a significant initiative in the packaging market. It is user-friendly, sustainable and scalable and features advanced technology. Using brand new technology, the products are pressed into their final form and their properties can be tailored during the production process according to the intended purpose. The raw material of Muoto grows in northern, sustainably managed forests and is fully traceable.

Both renewable and recyclable, Muoto is a good alternative to fossil plastic, for example, in food packaging, including serving dishes or containers of various sizes and shapes. Packaging that is produced to meet a specific need is ideal for reducing food waste.

Both renewable and recyclable, Muoto is a good alternative to fossil plastic, for example, in food packaging, including serving dishes or containers of various sizes and shapes. Packaging that is produced to meet a specific need is ideal for reducing food waste.

“Plastic is everywhere. It will continue to have a role in the future, but the growing packaging industry requires a variety of new sustainable alternatives; Muoto is our answer to these needs. This brand new, wood-based packaging has attracted a great deal of interest in our customer base,” says Jarkko Tuominen, Metsä Group’s Project Director.

Muoto has just got off the ground, and now its product features and production method are being further developed and the product’s market potential is being tested. A well-recognised brand plays an important role in this work. If the market interest and the product viability can be proved on a large scale, Metsä Group will consider building a larger production unit.

Learn more about Muoto online at muoto.io.

Metsä Spring

www.metsaspring.com

Innovation company Metsä Spring invests expertise and financial resources into initiatives with the ambition to reshape the forest-based bioeconomy, aiming to increase the value for Metsä Group’s stakeholders in the long-term.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by nearly 100,000 forest owners.

Stora Enso assesses growth opportunities in recycled packaging materials with a conversion in Langerbrugge

Stora Enso has started a feasibility study at its paper production site in Langerbrugge, Belgium, for the conversion of one of the two paper lines into a high-volume recycled containerboard line. Aligned with Stora Enso’s strategic focus on renewable materials, the investment would support the growth opportunity created by the increasing demand for recycled packaging board.

Stora Enso’s Langerbrugge site currently has two paper lines in production, one for newsprint and one for supercalendared (SC) magazine paper. The feasibility study will focus on the conversion of the site’s newsprint paper line. The conversion would enable Stora Enso to further grow its recycled and recyclable packaging materials capacity and to meet the growing demand in end-use segments such as industrials, e-commerce, furniture and electronics.

The feasibility study is expected to be finalised in the first half of 2023. Depending on an investment decision, the converted line is expected to be in production during 2025. The annual capacity would be 700,000 tonnes of testliner and recycled fluting grades and would generate annual sales of approximately EUR 350 million when run at full capacity. The total investment for the conversion is estimated to be approximately EUR 400 million.

“Today we produce recycled containerboard in Poland, mainly for the Eastern European market. A conversion in Langerbrugge would establish a competitive position for us in Western Europe as well. In addition to sourcing materials for recycled containerboard, the study will also assess the handling of different incoming recycling streams, including laminated grades. Having successfully completed conversions at other sites, we would be able to leverage important learnings from those projects,” says Hannu Kasurinen, Executive Vice President, Packaging Materials division.

Stora Enso announced in March this year that it was initiating a sales process for possible divestment of four of its five paper production sites. The Langerbrugge site has been excluded from this process and will be retained within the Group. The future of the Langerbrugge site’s SC paper line will be evaluated if a decision is made regarding the conversion of the newsprint paper line.

“If an investment decision is made, the Langerbrugge site will continue to serve our paper customers as usual until at least the end of 2024. The central location, experienced personnel and good access to recycled fiber remain core strengths of the site,” says Kati ter Horst, Executive Vice President, Paper division.

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

VTT develops transparent cellulose film to replace traditional plastic in food packaging

VTT Technical Research Centre of Finland is piloting a new transparent cellulose film that reduces microplastic.

Food packages fulfil their most important tasks when they protect food and minimise waste. Thin plastic films are nevertheless difficult to recycle, and they often end up in the wrong places after use.

VTT has developed a solution to the problem of plastic packaging. Regenerated or recrystallised cellulose can replace plastic films.

Technology Manager Heli Kangas

Technology Manager Heli Kangas

“We can produce transparent and flexible cellulose film. The consumer cannot distinguish between the crystal-clear material and traditional oil-based plastic. Cellulose film can resist dampness, but in nature it disappears as completely as a sheet of paper does. The product is biobased and biodegradable”, says VTT Research Professor Ali Harlin.

In addition to their protective properties, plastics are important because consumers want packages that allow them to see the product itself. However, once they have been used, many packages are sources of problems. If a package has both paper and plastic, the consumer may wonder if it can be recycled with cardboard, or if the plastic needs to be torn off first. Some of the materials have alternating layers of fibre and plastic. Many packages are placed among mixed waste by people who cannot think of a better way of disposing of it. Plastic that ends up in a cardboard recycling bin can be removed, but the plastic usually ends up incinerated.

“The cellulose film developed by VTT can replace plastic as a more climate-friendly solution. It also makes recycling easy, as it can be placed in cardboard recycling along with other packages”, says Atte Virtanen, Vice President, for Biomaterial processing and products at VTT.

Cellulose film pilot line in VTT Bioruukki

Cellulose film pilot line in VTT Bioruukki

Finland remains far from the goals set by the EU for reducing the environmental harm caused by plastics. At present, about 20 percent of plastics are collected, and even less end up recycled. Under the EU target, 55 percent of plastics should be recycled by 2025.

Plastic film market is worth 110 billion dollars

Finland is currently more of a packaging material country than a printing paper country. Last year the value of sales of cardboard exceeded that of paper for the first time. The forest industry is looking for new products with a big market, which brings value-added. Flexible, transparent cellulose film is one such product. The world market for plastic films was about 110 billion dollars last year.

VTT's unique expertise has been used in cellulose film as a replacement for plastic.

“VTT has researched cellulose films for more than ten years, and for more than six years on regenerated cellulose in transparent films”, Virtanen says.

The production of packaging material is in the pilot phase, and it could be in extensive industrial use in 5–7 years.

VTT is a visionary research, development and innovation partner. We drive sustainable growth and tackle the biggest global challenges of our time, and turn them into growth opportunities. We go beyond the obvious to help society and companies to grow through technological innovations. We have 80 years of experience in top-level research and science-based results. VTT is at the sweet spot where innovation and business come together.

VTT – beyond the obvious

SupplyOne Highlights Extensive Range of High Quality Pouches for Primary Food Packaging

Pouch Solutions to Protect and Showcase Food Products

SupplyOne, Inc., the largest independent supplier of corrugated and other value-added packaging products, equipment, and services in the U.S., highlights its stock and custom pouches for packaging protein, seafood, and dairy.

As both a manufacturer and distributor of packaging products, SupplyOne offers solutions for any food packaging application, with unparalleled levels of quality, safety, protection, and design. SupplyOne packaging solutions safeguard food, increase shelf-life, create display-case standouts and withstand the rigours of transit and storage. They enable food manufacturers to expand their trading area and simplify quality management.

Primary Food Packaging Pouches

Stand-up pouches are the new go-to option for many retailers who want their products to garner attention on the shelf while maximizing shelf space. SupplyOne offers stock and custom pouches in clear, standard, and high barrier formats. Stand-up pouch features include re-closable zippers, easy-opening tear notches, and brilliant clarity.

Stand-up pouches are the new go-to option for many retailers who want their products to garner attention on the shelf while maximizing shelf space. SupplyOne offers stock and custom pouches in clear, standard, and high barrier formats. Stand-up pouch features include re-closable zippers, easy-opening tear notches, and brilliant clarity.

Vacuum pouches feature special barrier properties and are engineered for high performance. SupplyOne products are designed to work well in most vacuum chamber equipment producing predictably-reliable seals to ensure that proteins, cheese, and seafood are safe, have a quality shelf-life, and deliver strong optical properties.

Consulting Expertise to Lower Total Cost of Ownership

The SupplyOne Food Packaging Program offers customers the opportunity to work with a single point of contact, a food industry packaging expert, and receive recommendations to amplify purchasing efficiencies, slim down inventory investment, raise employee productivity and free up production space. This program is guaranteed to generate savings within 30 days.

About SupplyOne

SupplyOne is the largest independent supplier of custom corrugated and other value-added packaging products, equipment, and packaging-related services in the U.S. The company provides mid-sized manufacturers, food processors, and medical and e-commerce companies with industry-leading packaging programs and complete packaging solutions to reduce its customers’ total cost of packaging ownership from a single point of contact. The result? Better packaging, and enhanced efficiencies, speed to market, and cash flow. Since its founding in 1998, SupplyOne has become the acquirer of choice for privately-held speciality corrugated packaging manufacturers and value-added packaging distributors. For more information about SupplyOne’s packaging solutions, contact SupplyOne at 484-582-5005, email This email address is being protected from spambots. You need JavaScript enabled to view it. or visit https://www.supplyone.com/.

Walki introduces a broad portfolio of recyclable materials for the growing frozen food segment

Walki is answering to the growing demand for frozen food by expanding its portfolio of recyclable materials.

The global market for frozen food is expected to grow to 322 billion euros by 2026. Although the demand is growing globally across all age groups, it is especially popular among younger consumers.

- Walki®EVO Seal and Walki®Opti Seal are recyclable paper-based packaging intended especially for pillow-pouches for frozen food.

- Lamibel®MDO-PE is a film-based material for pillow pouches made of reverse printed MDO-film and solvent-free laminated with low sealing LDPE.

- Walki®Pack Tray is a board-based tray suitable for frozen ready-made meals, designed to replace aluminium, plastic or plastic-coated trays.

The global market for frozen food is expected to grow to 322 billion euros by 2026. Although the demand is growing globally across all age groups, it is especially popular among younger consumers.

"Frozen food is an ideal way to prolong shelf life without losing out on the vitamins. It is also an excellent way to combat food waste. This is important as up to 9 % of global carbon emissions can be attributed to food waste, especially fruit and vegetables", says Dudley Jones, Consumer Sales at Walki.

Walki is introducing a broad portfolio of different materials, including printed solutions, to suit the needs of the frozen food market with the aim of making the packaging fully recyclable in the paper stream.

"Frozen food places high demands on the packaging. It needs to be both sturdy and puncture-resistant to handle diverse situations like pressures of sealing and mechanical tear during transportation. The packaging also needs to withstand variability in temperatures as some frozen food is defrosted in its packaging", explains Jones.

Walki®EVO Seal and Walki®Opti Seal are recyclable paper-based packaging intended especially for pillow pouches for frozen food. Walki®EVO Seal has a dispersion coating as a barrier against water vapour and grease while Walki®Opti Seal has an optimised PE-extrusion coating.

"The dispersion coating makes Walki®EVO Seal recyclable in the waste-paper stream without any separation process, while the minimised PE-coating on Walki®Opti Seal makes it suitable to be recycled with paper with an acceptable fibre yield", says Andreas Rothschink, Head of Product Development at Walki.

Both are suitable for all kinds of frozen food: vegetables, seafood, and bakery products to name a few.

Lamibel®MDO-PE is a film-based material for pillow pouches made of reverse printed MDO-film and solvent-free laminated with low sealing LDPE. Thanks to the MDO technology, the film thickness is minimized while performance is maximized by replacing other sorts of materials such as PP- or PET-films.

"This combination of two PE-films makes the packaging fully recyclable in the plastics stream. The stretched film has better optics with high stiffness and mechanical properties than standard PE. The film can also be transparent, allowing the consumer to see the product", says Rothschink.

Lamibel®MDO-PE is an ideal material for all types of packaging (doypack, flowpack, pouches, etc.) as well as all kinds of frozen food like vegetables, sharp-edges seafood and bakery.

Walki®Pack Tray is a board-based tray suitable for frozen ready-made meals, designed to replace aluminium, plastic or plastic-coated trays.

"The tray is easy to fill, transport and store, and is also the convenient choice for the consumer as the fibre-based tray is safe to use in microwaves and in conventional ovens up to 220 degrees for up to 60 minutes," says Jones.

The tray material is 100% PET free and recyclable in the paper stream.

Company Profile Walki

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero-waste future in packaging and promote the use of energy-efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy-saving performance materials.

Walki is a growing international group organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia.

Metsä Group’s and Valmet’s 3D fibre product demo plant is now operating

The operations at Metsä Group’s and Valmet’s 3D fibre product demo plant in Äänekoski has begun. At the end of 2020, Metsä Group’s innovation company Metsä Spring and Valmet announced they would be investing a total of approximately 20 million euros in the demo plant.

The demo plant is part of Metsä Group’s integrated mill site in Äänekoski, and it produces finished 3D fibre packaging products directly from wet pulp without intermediate phases. The moulded fibre-based packaging can replace plastic for example in food packaging. The demo plant currently employs approximately ten people.

“Our fibre-based packaging products are a significant new initiative in the global packaging market. The novelty in our products include their layered structure, which, in turn, allows their production in a raw material and energy efficient manner applying a highly automated production process. The layered structure also allows the products to be easily modified for different purposes. The customers’ reception of the new product has been very positive. We know we’re on the right path,” says Metsä Group’s project lead, VP, Jarkko Tuominen.

3D fibre product

3D fibre product

“We are very satisfied with our cooperation with Metsä, and we think the mould casting technology is an excellent prospect as a future packaging solution. This is a good example of Valmet’s capacity for developing new technology, and I’m especially proud of how we’ve been able to make use of our broad process expertise in this project,” says Petri Rasinmäki, VP, Board and Paper Mills Business Unit at Valmet.

The demo plant has started a testing and development phase that will last a few years. The goal of this phase is to prove the competitiveness of the production and of the product in the packaging market. If this goal is achieved, it will be possible to consider building a larger production unit.

The 3D fibre product is renewable, recyclable and biodegradable, and its raw material comes from sustainably managed forests, which are primarily owned by Finnish families. Metsä Group is actively developing new business opportunities and researching new wood-based products that can increase the value of its owner-members’ forests. Moreover, the Äänekoski site is also the home of another demo plant, namely a facility developing a process for the production of the Kuura textile fibre.

Pictures of 3D fibre products and demo plant

Metsä Spring

www.metsaspring.com

Innovation company Metsä Spring invests expertise and financial resources into initiatives with the ambition to reshape the forest-based bioeconomy, aiming to increase the value for Metsä Group’s stakeholders in the long-term.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by nearly 100,000 forest owners.

BIO-LUTIONS partners with PulPac - sets up large-scale Dry Molded Fiber production

The German Clean Tech Startup BIO-LUTIONS and PulPac, the Dry Molded Fiber pioneer, are natural allies in their objective to replace single-use plastics globally. Together with machine suppliers they have developed a Dry Molded Fiber production line, set to start production in the new BIO-LUTIONS factory in Schwedt/Oder, Germany by the summer of 2022.

BIO-LUTIONS mechanically converts agricultural residues into unique, self-binding, durable fibcro® natural fibers. This patented method eliminates the need for binding agents or chemical cellulose isolation, as the whole fiber is used. From these fibers together with the dry moulding technology, BIO-LUTIONS will produce a variety of sustainable single-use disposable products such as service food items (cutlery and tableware) as well as protein, fruit and vegetable packaging. By introducing the new dry moulding technology provided by PulPac, production can now benefit from the unique cost and quality advantages compared to existing cellulose forming solutions.

The cooperation with PulPac opens the door to an additional production technology for fibre moulding, allowing for technology diversification as well as optimisation of dry moulding processes. The Dry Molded Fiber technology saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is extremely fast and more efficient than conventional fiber forming methods. While Dry Molded Fiber technology will not be used for all BIO-LUTIONS’ products, it does offer significant production advantages for a large variety of single use products.

“Each company brings something unique and valuable to the table. Being able to create partnerships that prioritize creating real solutions to the plastic age, rather than trying to build walls is what will make true change possible. That is why we are very excited to include dry moulding from PulPac as a second core production technique” Eduardo Gordillo, CEO BIO-LUTIONS.

The new factory in Germany will be up and running this summer and brings together two unique innovations, BIO-LUTIONS’s fibcro® natural fibers and PulPac’s Dry Molded Fiber technology – delivering truly sustainable and competitive fiber-based packaging to the world.

The new factory in Germany will be up and running this summer and brings together two unique innovations, BIO-LUTIONS’s fibcro® natural fibers and PulPac’s Dry Molded Fiber technology – delivering truly sustainable and competitive fiber-based packaging to the world.

“BIO-LUTIONS is an innovative and fast-moving partner. We share a doer attitude and a clear-cut commitment to replace single-use plastics at scale. Having products on the market already this year will take the concept of sustainable packaging a big leap forward. We look forward to a long-term partnership where we can share know-how and expertise to leverage the full potential of dry moulding within BIO-LUTIONS’ operations and customer network.” says Linus Larsson, CEO, PulPac AB.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

About BIO-LUTIONS

BIO-LUTIONS is a Hamburg-based green tech start-up that has developed its own innovative natural fibre technology, used to produce sustainable packaging and disposable tableware. The production process gives a second life to currently unused agricultural residuals as raw material to replace con-ventional plastic and paper products. BIO-LUTIONS was founded in 2017 and is currently expanding in Asia and Europe. With the purely mechanical process BIO-LUTIONS creates stable structures and products without additional binding agents. The application of this innovative fibre technology was

developed in Germany, at their technical centre in Schwedt, Brandenburg. The first factory was opened in Bangalore, India and now follows the new production facility in Schwedt, Germany. As part of the Innovation Campus Schwedt, BIO-LUTIONS is a part of the new hub for innovative technology in Brandenburg.

For more information, please visit: www.bio-lutions.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy. It leverages globally available, affordable, and renewable cellulose fibers to produce high performance fiber-based packaging and single-use products with highly competitive unit economics. Dry Molded Fiber also saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is up to ten times as efficient as conventional fiber molding invented over 100 years ago.